Introduction

————————————————-

“If all you have is a hammer, everything looks like a nail”

Abraham Maslow / Abraham Kaplan

They say there is a tool for every job, and the quote couldn’t ring truer when it comes to WiFi design in complex environments.

This is very much an appreciation post, as I have been using Acceltex products for as long as I can remember, especially for specialist use cases, such as within industrial, manufacturing and warehouses with narrow aisle racking (VNA). Still, the opportunity to do a side-by-side comparative analysis of different antennas has never presented itself.

Thanks to the excellent design tools that we have at our disposal these days, many of the initial questions related to antenna selection are generally addressed before samples are procured and an APoS survey is conducted to validate that we can meet the customer requirements for a particular project, and as a result, I rarely find the time need to test a large selection of different antennas at any one time.

Luckily as wireless engineers, with Acceltex, and their distributor within the UK, Open Reality, both being progressive companies, they recognise the value of providing these products to engineers, so that they can be taken into the field and used during the design/pre-sales process, this has proven invaluable time and again for evaluating different use cases.

Special thanks to Matthew Wenham (Acceltex) and Joseph Chorley (Open Reality) for always being on hand to provide access to this equipment!

Objectives

An opportunity recently presented itself to do some comparative analysis, for this particular project it was requested that we perform an overhaul of an existing warehouse wireless solution that it no longer considered fit for purpose, the key motivation for the uplift was because existing hardware has reached an end of life milestone, and that the customer is to soon begin on a path of modernising their logistics operations, bringing new, more capable devices to bear, which require a more robust solution that will support the business for at least the next 5-7 years.

The current design utilises directional antennas, situated on opposing isles, but spaced every 3rd aisle, which has led to poor coverage within the middle of the aisles and indeterministic roaming performance, especially vehicle mount computers (VMCs) and mobile devices.

The existing antennas have a wide horizontal plane (Azimuth) which does provide coverage for adjacent aisles but coverage is heavily influenced by the amount of inventory within the warehouse, which fluctuates based on seasonal demand.

This location, having surveyed it previously, presented a great opportunity to evaluate different options as there was a genuine query related to which product would best meet the customer’s requirements, both would feasibly work, but which was best, and what factors came into play when making the decision.

Whilst I try not to chase perfection in every given scenario, any opportunity to minimise risk is desirable.

Requirements

When choosing the correct antenna for the intended use case, the following requirements were defined:

- Minimum RSSI of -65dBm within the entire length of each VNA.

- Measured from the AP and the Client (LCMI Device)

- Minimum SNR of 25dB

- Measured from the AP and the Client (LCMI Device)

- No co-channel contention on 5GHz using a repeating channel plan (Band A/B)

- Minimal bleed between opposing VNAs

- Flexibility to install overhead or end of aisle w/ overhead preferred for a clearer line of sight.

* Very Narrow Aisle Pallet Racking (VNA) is an adaptation of standard adjustable pallet racking systems, but compacted into a very small area, creating a high-density storage system that makes it possible to increase the capacity of the warehouse without expanding the space.

Antenna Selection

From experience, there have always been two products that have stood out from the crowd for coverage within aisles, but have also added a 3rd to cover another particular use case also often seen in these environments.

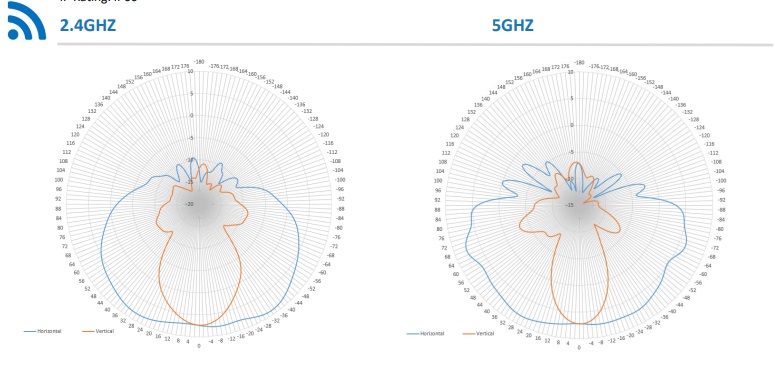

- Acceltex ATS-01088 – (ATS-OP-245-13-4RPTP-36) 2.4/5 GHz 13 dBi 4 Element Indoor/Outdoor Patch

- Acceltex ATS-01125 – (ATS-OP-245-8-4RPTP-36) 2.4/5 GHz 8 dBi 4 Element Indoor/Outdoor Patch

- Acceltex – ATS-02695 – 2.4/5 GHz 4 dBi 4 Element Indoor/Outdoor 90×90 Patch

- Although not applicable to providing coverage within VNAs, it offers an excellent option for overhead, focussed coverage for large, open areas, such as loading bays and picking/despatch areas.

Due to their unique azimuth and elevation profiles, matched with options for high and medium gain to increase receiver sensitivity at greater distances, they cover a wide range of use cases where side lobe bleed between individual racking needs to be carefully managed, especially when deployed in large numbers, either overhead or end of aisle, in what are typically very reflective environments.

This is not intended to be an in-depth product review, there are certainly other options within the market that offer similar attributes such as the Ventev M6130130MP1D0006W but felt it useful to highlight through analysis conducted in the field, why one product may be chosen over another and how pre-deployment validation and understanding of RF signal propagation can help engineers make better decisions when selecting a particular product for specific use case.

The access point (AP) that will be used for the deployment is a Cisco Catalyst 9120 AXE, thus for this post, we are using the 4 Element models w/ RPTNC connectors, on 2.4 and 5GHz only, but other options are available and there is a broad range of vendor support, these can be easily filtered out for compatibility on the Acceltex website.

NB: This post isn’t a deep dive into specifics relatable to the physical installation, mounting or aesthetics, but is purely focused on the RF coverage provided by each antenna.

Antenna Specifications

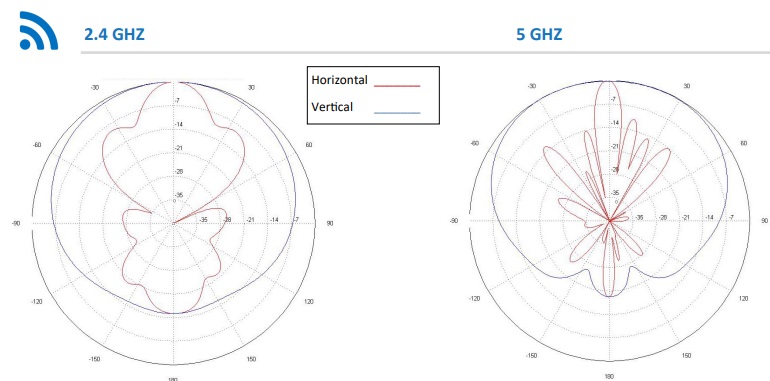

Acceltex – ATS-01088 – 2.4/5 GHz 13 dBi 4 Element Indoor/Outdoor Patch

The SKU for this model used to be: ATS-OP-245-13-4RPTP-36

Each antenna element is optimized for Wi-Fi operation on both 2.4 and 5 GHz. This antenna comes with integrated mounting holes in the corners of the radome and leads exiting the bottom of the antenna for a flush wall mount. This highly versatile antenna is suitable for a broad range of indoor and outdoor applications where focused RF coverage of an area is desired.

Due to the unique propagation properties of this antenna, it is perfectly suited for warehouse deployments where Very Narrow Aisle Pallet Racking is used and achieves a uniform floor-to-ceiling coverage pattern when deployed overhead, validated up to heights of 50ft (15m) and aisle length of upto 100m.

- Antenna Type: Patch

- Frequency Range: 2.4-2.485/5.15-5.85 GHz

- Gain: 13 dBi

- Polarization: Horizontal

- Horizontal Beamwidth: 15

- Vertical Beamwidth: 120

- VSWR: ≤1.5:1, Max 2.0

- Isolation: > 30 dB

Acceltex – ATS-01125 – 2.4/5 GHz 8 dBi 4 Element Indoor/Outdoor Patch

The SKU for this model used to be: ATS-OP-245-8-4RPTP-36

Each antenna element is optimized for Wi-Fi operation on both 2.4 and 5 GHz. This antenna comes with integrated mounting holes in the corners of the radome and leads exiting the bottom of the antenna for a flush wall mount.

Due to the unique propagation properties of this antenna, it is perfectly suited for warehouse deployments where Very Narrow Aisle Pallet Racking is used and achieves a uniform floor-to-ceiling coverage pattern when deployed overhead, validated up to heights of 30ft (10m) and aisle length of upto 50m.

- Antenna Type: Patch

- Frequency Range: 2.4-2.485/5.15-5.85 GHz

- Gain: 8dBi

- Polarization: 2 Vertical, 2 Horizontal

- Horizontal Beamwidth: 125°/114°

- Vertical Beamwidth: 35°/24°

- VSWR: < 1.5:1\, max 2.0

- Isolation: > 20 dB

Acceltex – ATS-02695 – 2.4/5 GHz 4 dBi 4 Element Indoor/Outdoor 90×90 Patch

The SKU for this model used to be: ATS-OHDP-245-4-4RPTP-36

Each antenna element is optimized for Wi-Fi operation on both 2.4 and 5 GHz. This antenna comes with our integrated flush mount for surface mounting through a thin wall or enclosure door and also ships with an articulating wall and pole mount kit..

I wanted to include this one, as whilst it isn’t intended to be used for VNAs, it does serve another use case within warehouses, and loading bays, we’ll get onto that later!

- Antenna Type: Patch

- Frequency Range: 2.4-2.485/5.15-5.85 GHz

- Gain: 4dBi

- Polarization: 2 Vertical, 2 Horizontal

- Horizontal Beamwidth: 90°/90°

- Vertical Beamwidth: 90°/90°

- VSWR: <2

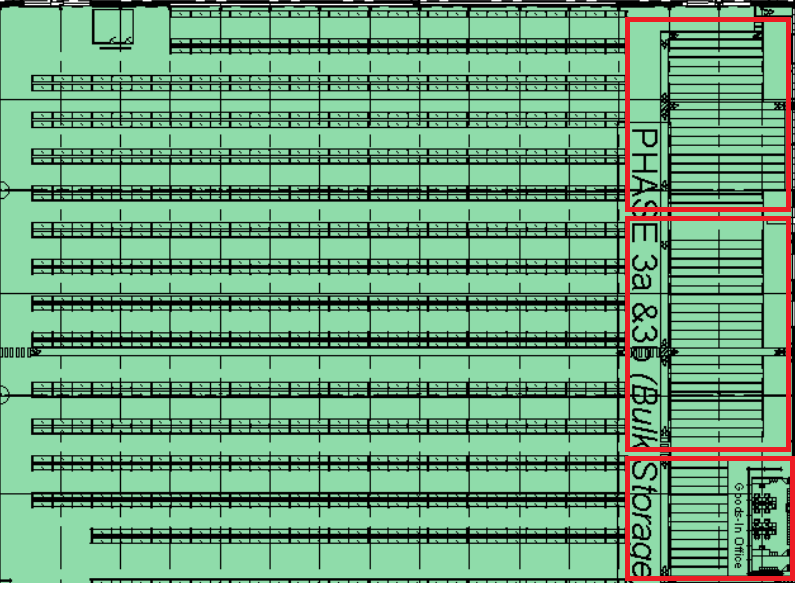

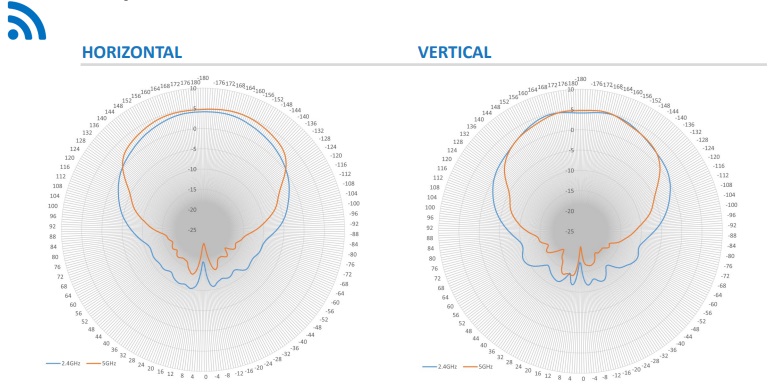

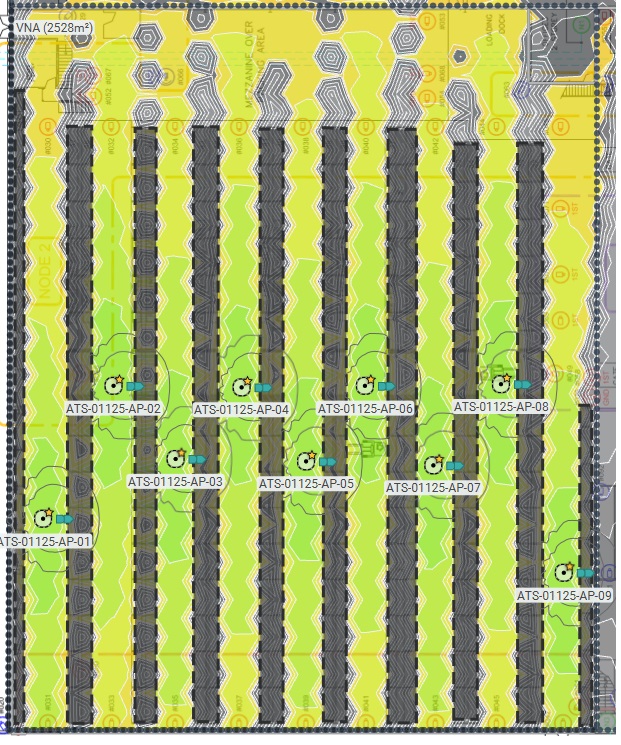

Predictive Design

This warehouse is quite small, with a total footprint of the racking area being ~2500m2, a floor-to-ceiling height of 13m and the length of each aisle measuring 46m.

It was the length of the aisles and racking height which prompted the question as to which antenna would be best suited, as both the 13 and 8dBi models could meet the minimum requirements.

In terms of options for installation, this was possible along the southern perimeter wall, firing down each aisle, but physical constraints on the opposing side made mounting on alternate aisles difficult, and in some instances untenable, as it doubles as a packing and despatch area with a mezzanine above. As such, an overhead approach was the preferred choice and formed the basis of the proceeding APoS survey.

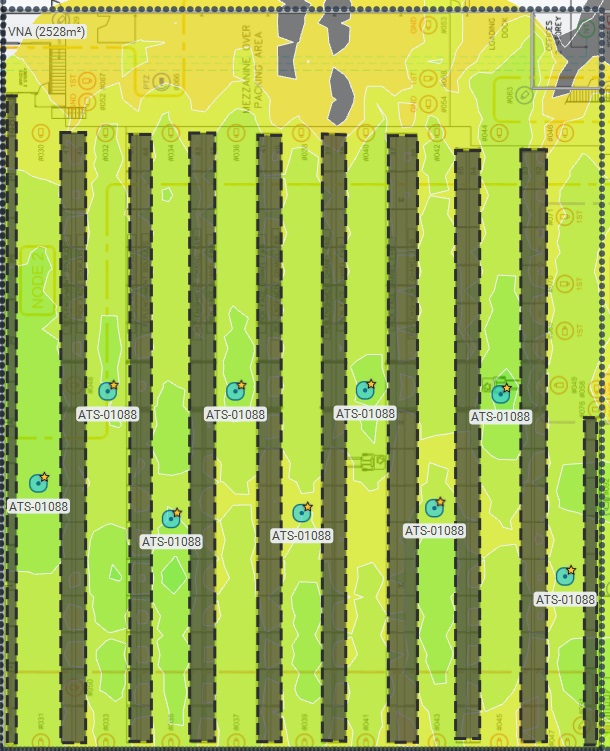

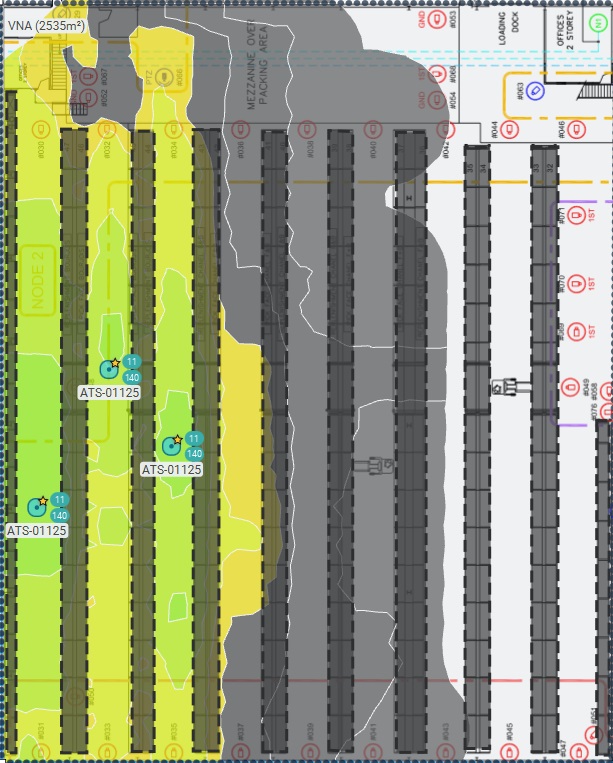

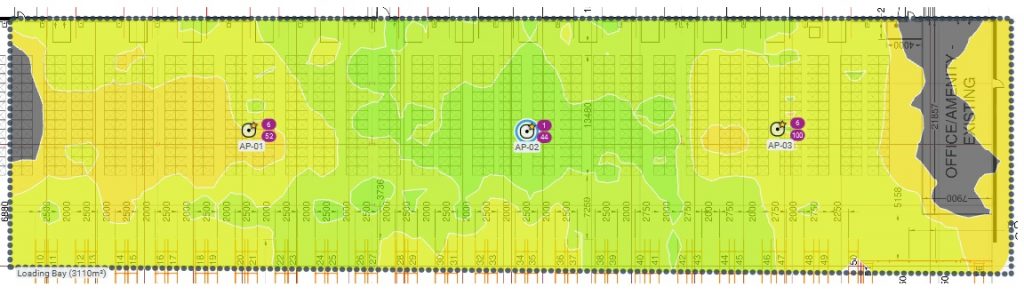

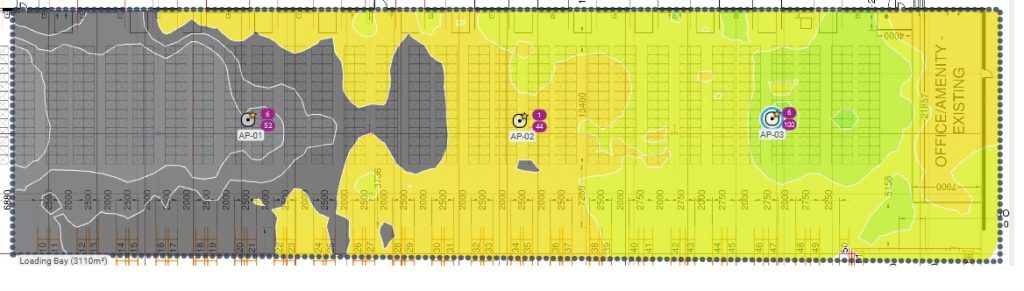

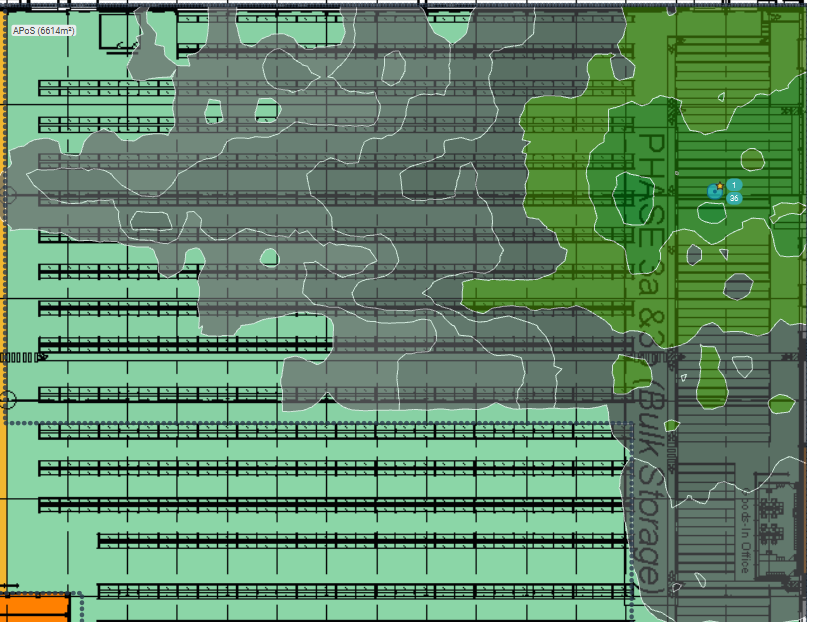

To begin with, measurements were taken to validate the length, width and height of the warehouse and VNAs, and then a predictive design was created within Ekahau AI Pro to simulate coverage of the two different antenna types. Ceiling and racking height was also taken into account, and reflected within Ekahau, although scanning of inventory in this warehouse only happens at ground level, thus not felt it was necessary to take measurements at the top of each rack.

As this warehouse had been previously surveyed and documented, it was much easier ahead of time to determine where apparatus could be mounted without causing an obstruction or to work around physical constraints as a result of the construction of the roof space.

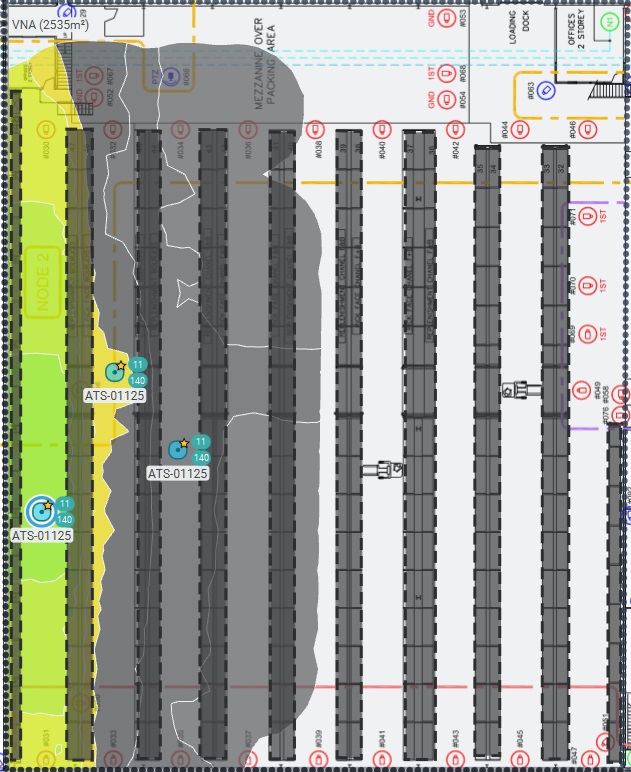

In all scenarios, the AP and Antenna were positioned on the floor plan, at the same height (8m), orientated to favour the wider horizontal or vertical beamwidth, focussing energy along the aisle and TxPower set on each radio (2.4GHz – 5dBm and 5GHz 11dBm) as a starting point.

The RSSI signal threshold within Ekahau is set to -65dBm and -25dB for SNR, the warehouse racking 12dB/m, which is an assumed value as part of the predictive model.

NB: Pay special attention to the orientation of these antennas and follow this guide to ensure that they are positioned to provide the correct coverage profile.

So far so good, both antennas, based on the same parameters tick all the necessary boxes, and without actually conducting an APoS survey you could say that with reasonable confidence, either solution would be adequate to meet the customer’s requirements.

The reality however is always different, which is why APoS surveys within complex environments are a necessity for mitigating any previously unforeseen risks and adapting the design to compensate accordingly where possible.

APoS Setup

To validate the predictive design and do a comparative analysis, both the AP and Antenna were mated to a Vantage Point Products | Wi-Fi Survey Mast Tripods 40ft / 12.2m / Four Storey Mast and powered using an Acceltex Accelerator Site Survey Battery Pack V2. If you’re in the market for a lightweight, retractable pole for conducting APoS surveys, I highly recommend speaking with Tom Hogan.

Using a laser range finder, the antenna was positioned at the same height (8m) as per the predictive design and orientated according to the predictive model.

The Accelex battery was affixed at ground level, powering a Cisco 9120 AXE AP in EWC mode, and attached to that a WLANPi, which was used for active measurements during the survey.

As I would consider best practice for APoS surveys, Radio channels have been configured at the upper limit of what is permissible for this model of AP, (2.4Ghz – CH11 and 5GHz – CH140) this ensures the worst possible scenario in terms of signal attenuation, as higher frequencies attenuate more the further distance they travel, although in free space this is not generally applicable, and more of an issue if RF signals need to penetrate other objects or surfaces, but it’s still a good practise I like to follow.

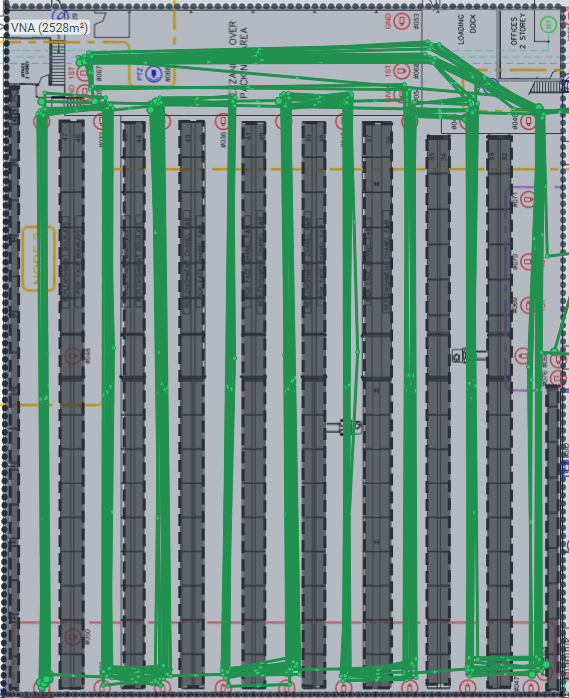

Warehouse Survey Path

When conducting the APoS survey, the same walking path was observed each time, covering each aisle in both directions to try and average out the measured data, also taking into account the additional attenuation added by the engineer wearing the Ekahau Sidekick at waist level. Whether or not this has a significant impact is subjective, that being said, Ferney Munoz gave a presentation at Wi-Co Manchester recently comparing 4 different survey tools, following identical survey paths, each carried by a different engineer, the results were very similar regardless of how the measurement device was worn on a persons body.

Comparative Results

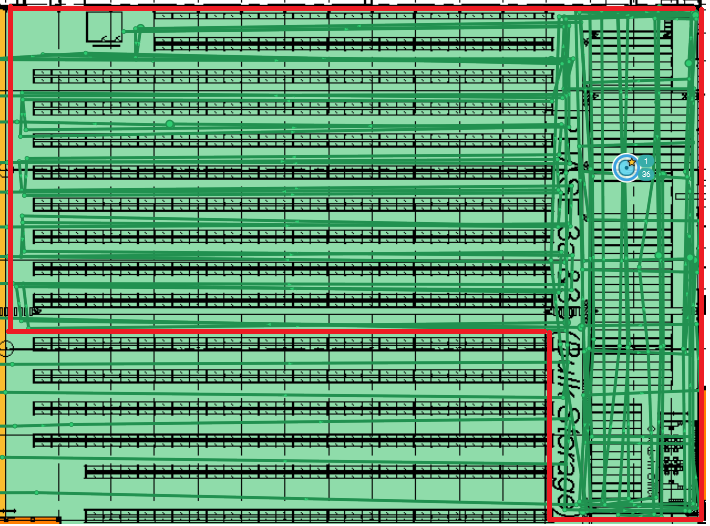

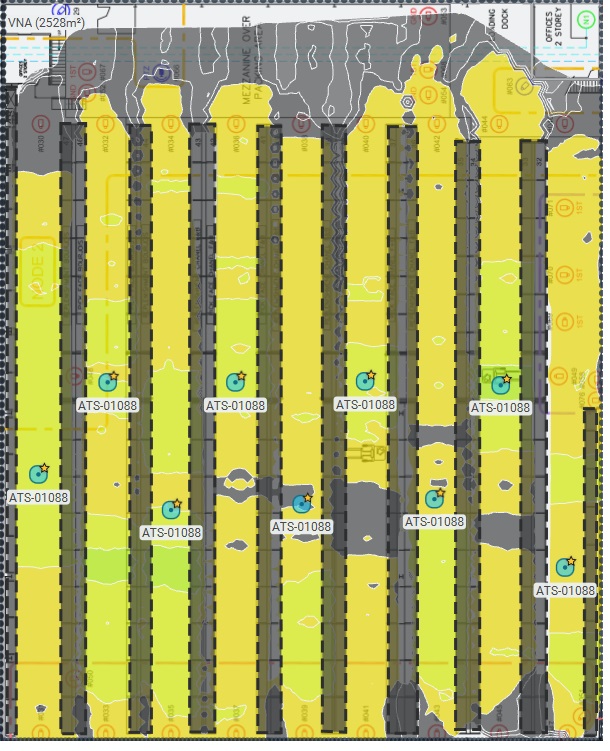

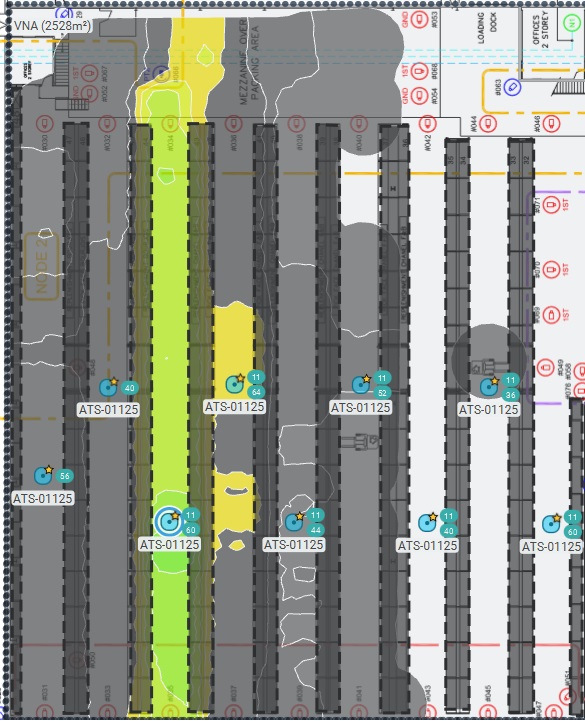

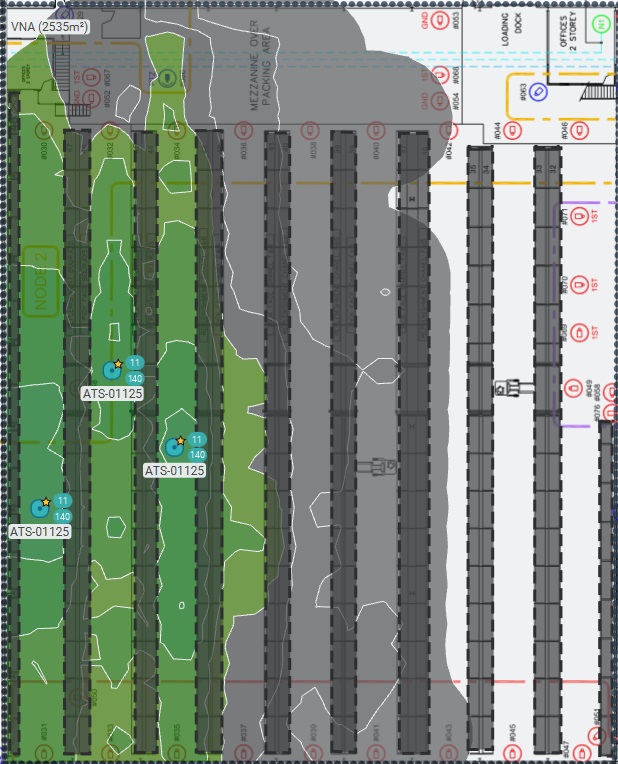

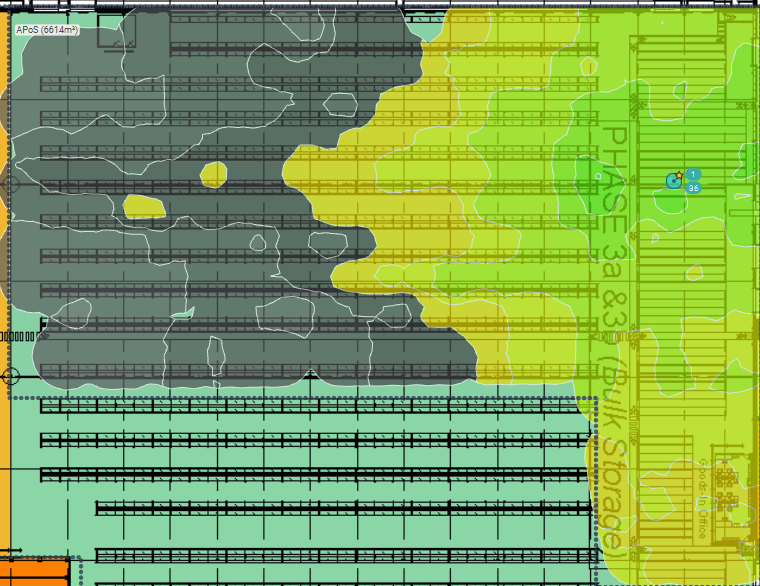

Acceltex – ATS-01088 – All VNA’s

As expected, the ATS-01088 antenna, with its 120° vertical, and very narrow 15° horizontal beamwidth provides excellent coverage along the full length of each rack. There were some discrepancies measured within some of the aisles, where we were not able to meet the minimum threshold of -65dBm, but instead recorded values of -66-67dBm, which are borderline, and warrant further investigation and client device validation. SNR in these areas however remains within the required threshold of -25dB for both measured and mobile coverage (Offset applied of -10dBm)

Warehouse Racking – Per Aisle View

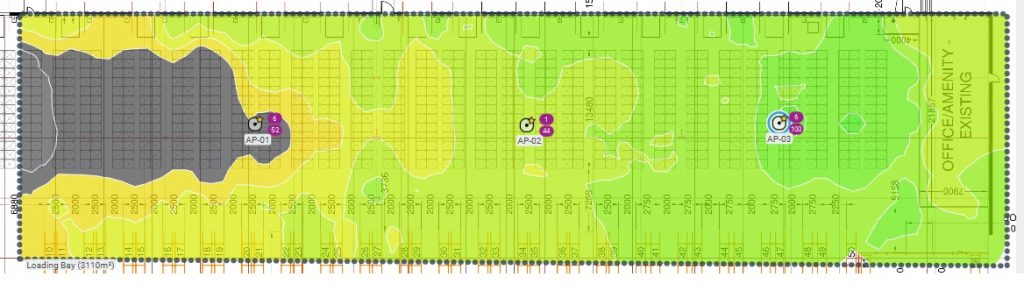

When we split out each AP individually, it is very promising to note that the bleed between aisles is limited, a strong testament to how this antenna has been designed.

The noticeable bleed between racks that you can observe is I believe due to a walkway running under the racking east to west, which is essentially free space, and even with the pallet racking directly above the walkway creating a shadow between the AP and the floor below, it is still enough to allow the signal to move relatively easily between racks, I also surmise that this is partially due to reflections caused within the physical environment.

If you discount the walkway running between the aisles, we can also observe the amount of isolation between aisles when measuring from the centre of the warehouse, from the point of view of the sidekick this is consistently between 13 and 16dBm.

This is particularly encouraging, as I would expect a client device to always prefer associating to the AP within the aisle as opposed to looking for other candidate APs in adjacent aisles, whilst maintaining a strong RSSI and SNR when moving along the racking area.

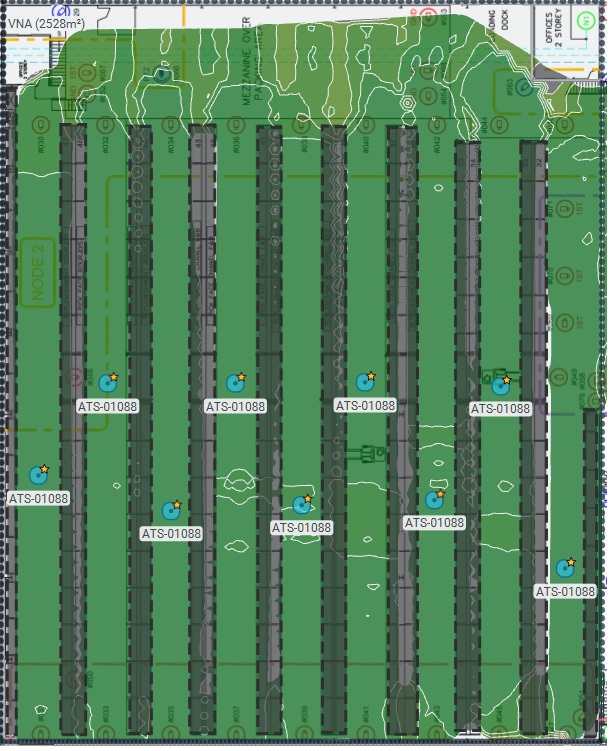

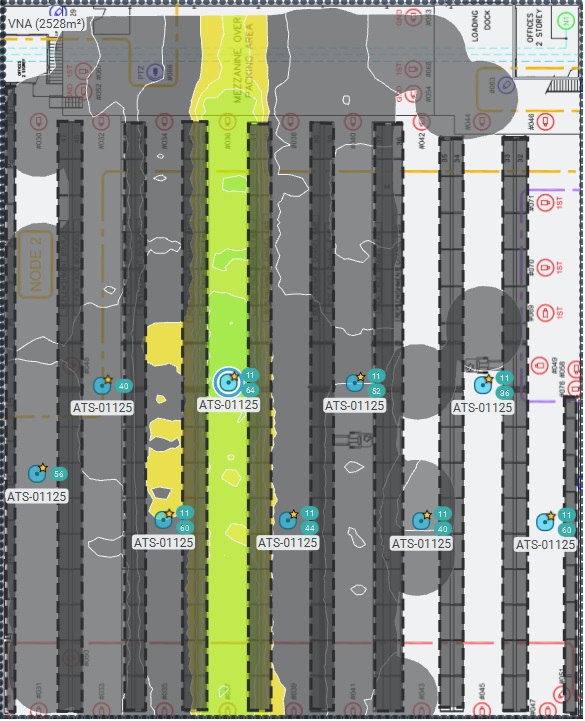

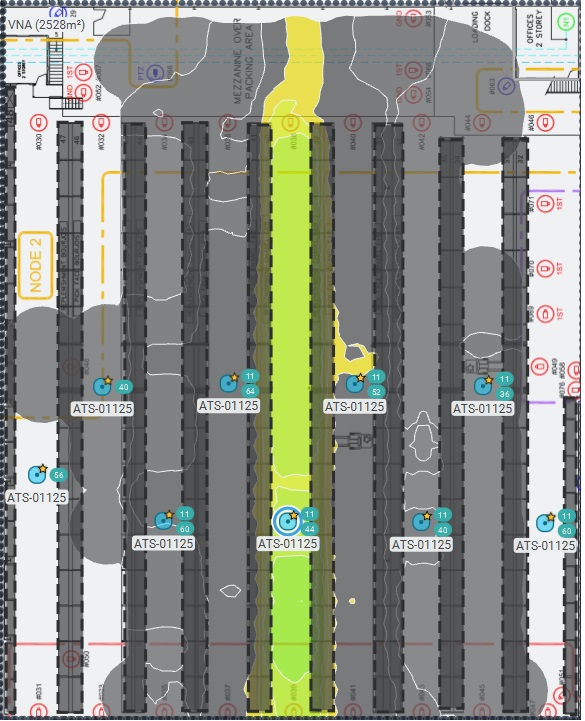

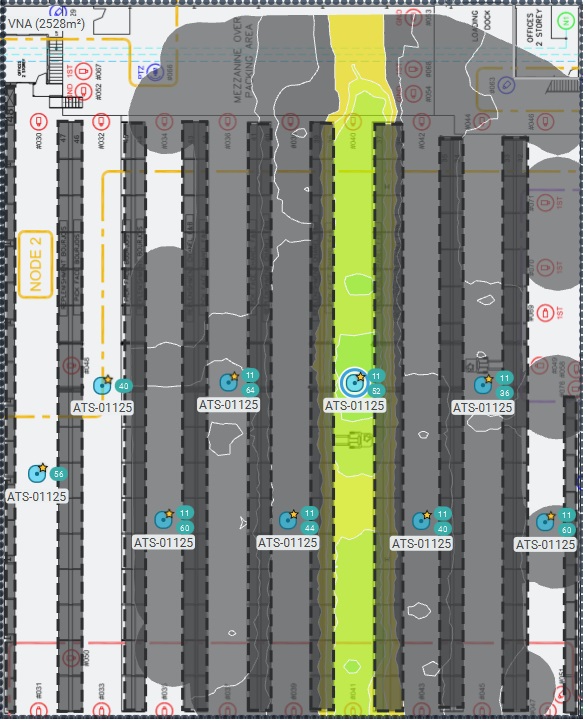

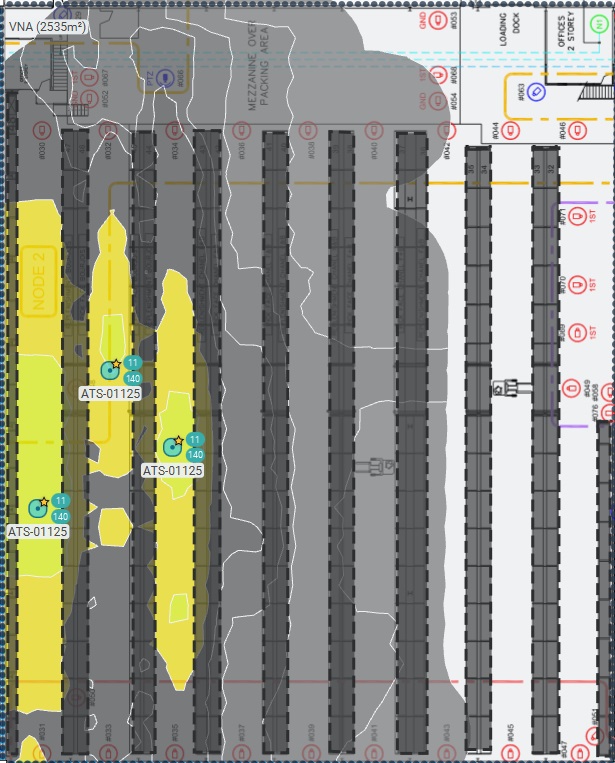

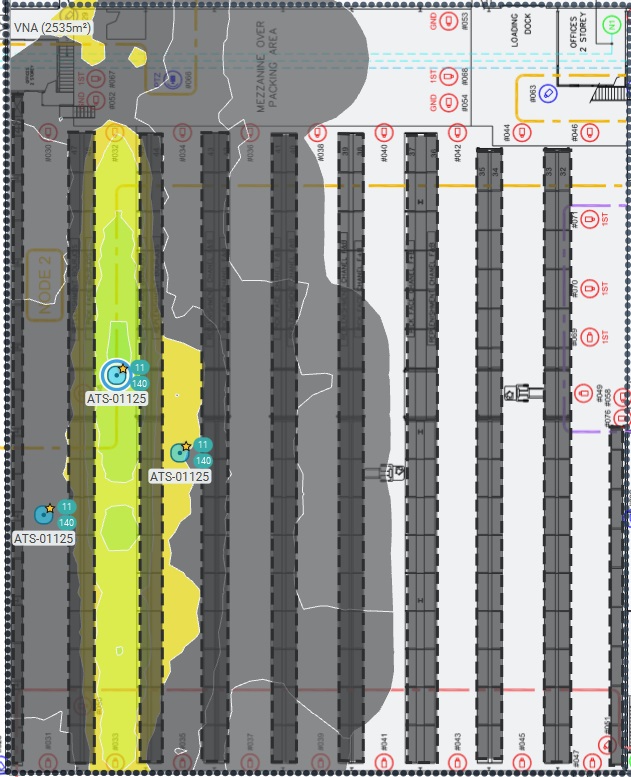

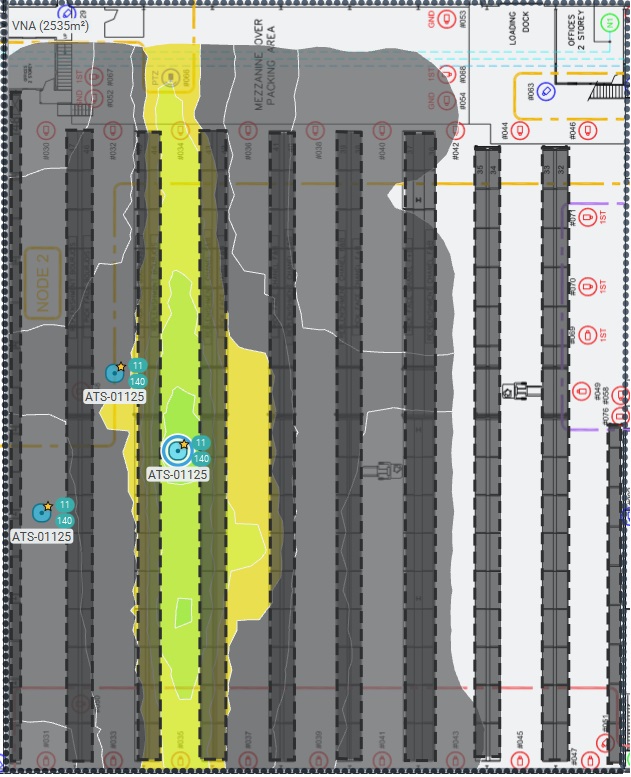

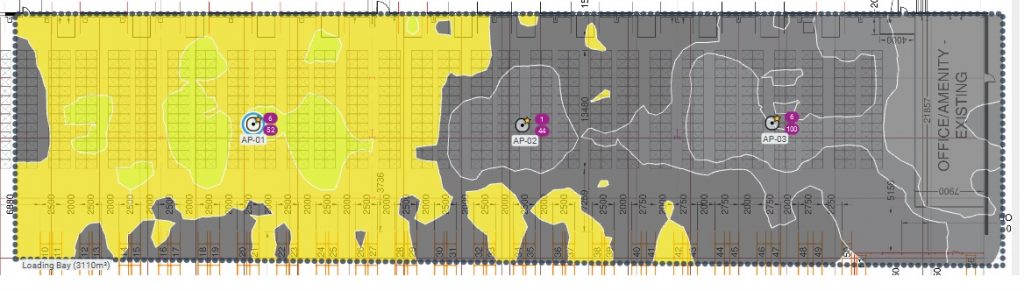

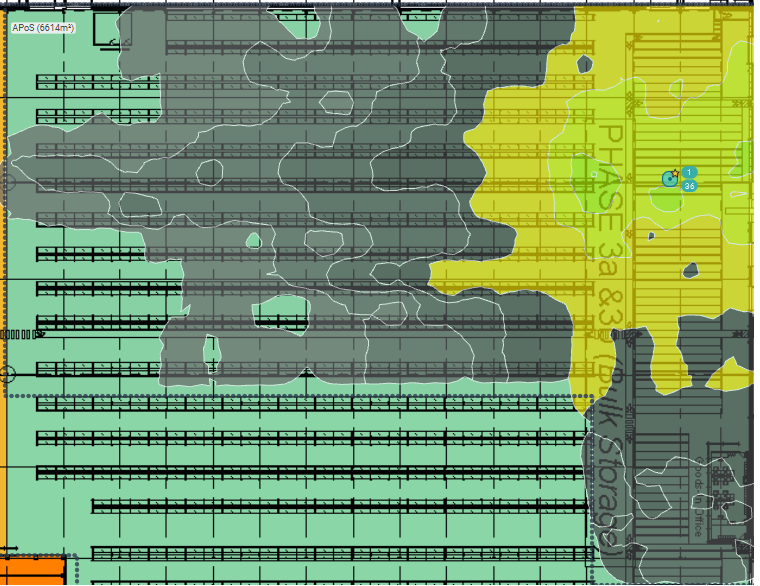

Acceltex – ATS-011255- All Some VNA’s

As usual, time was a factor, and due to a restricted working schedule, it being a Friday, and the warehouse operatives wanting to go home, it wasn’t possible to complete a survey of all the aisles using the ATS-011255 antenna, but the results that we were able to gather did confirm what I had hoped to demonstrate as part of this exercise.

Similar to the ATS-01088 antenna, the ATS-011255 has a horizontal beamwidth of 114°, which is in the opposite plane from the 13dBi model, and a relatively narrow 24° vertical beamwidth which again provides excellent coverage along the full length of each rack, but must be orientated perpendicular to the aisle it’s installed (Overhead)

Measured coverage is again excellent, even with the lower gain and same TxPower as the 13dBi model, but you can observe a noticeable drop below the required threshold of -65dBm when an offset is applied to simulate mobile device coverage, this is reflected in the SNR values also, metrics are not overly fatal (~20dB) but we could start to observe a noticeable impact in terms of user experience, depending on the use case and combined with how the device is being used and/or what it is attached too, often being a forklift truck or equivalent mobile elevating work platform (MEWP)

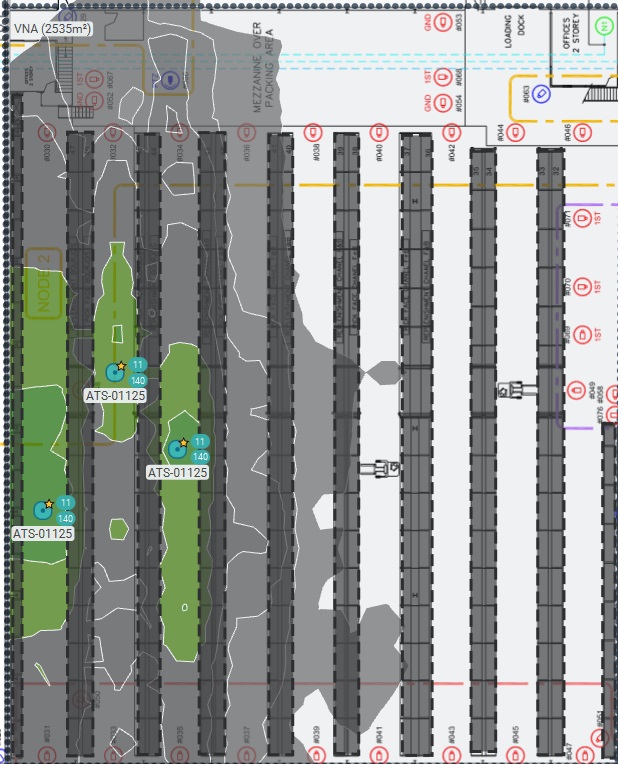

Warehouse Racking – Per Aisle View

Whilst I was fairly confident that we would observe a higher percentage of bleed between aisles when using the ATS-011255 antenna, it was encouraging that we could observe this in a live environment, this is one area where planning tools cannot accurately predict this, which, in my opinion, makes pre-deployment surveys essential, especially when it can be completed back to back, with the same physical constraints present, which in this instance is inventory stored within the racks, thus variables remain consistent.

There is also a measurable reduction in isolation between racks, as observed using the 13dBi antenna, this was recorded as between 13 and 16dBm, when reviewing the data from the ATS-010255 test, this has dropped to 10-11dBm. Not a significant difference, but again a useful marker to indicate the amount of isolation provided by the ATS-01088.

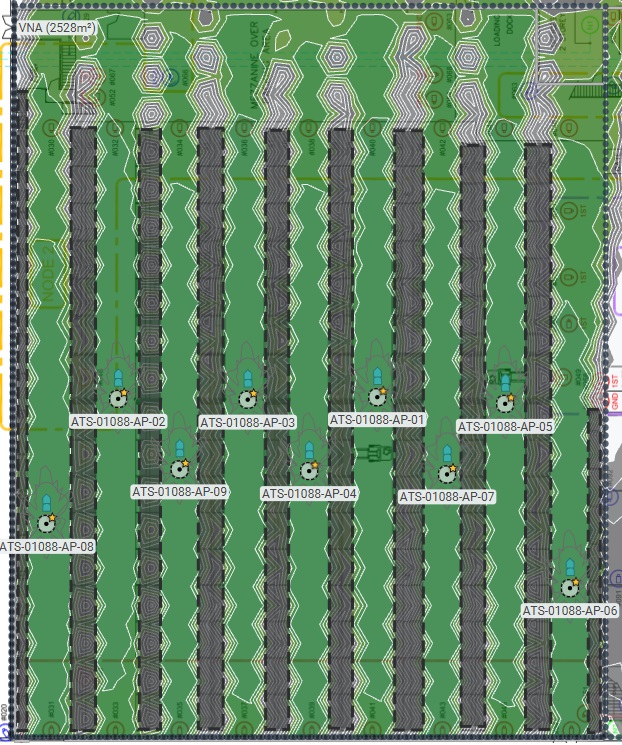

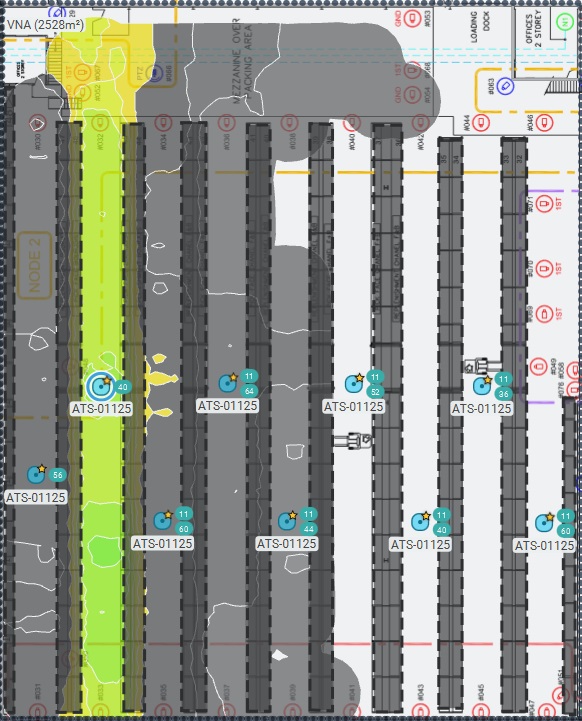

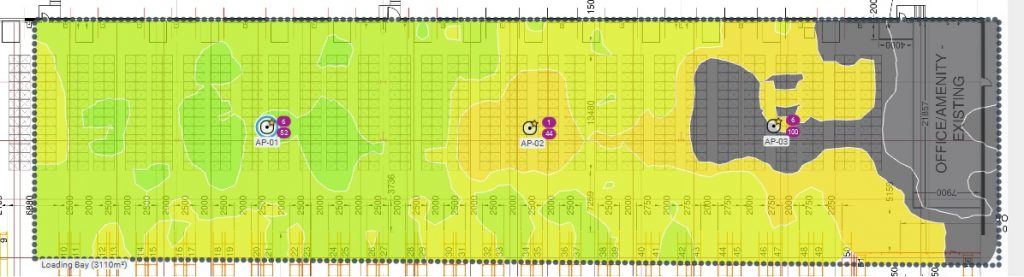

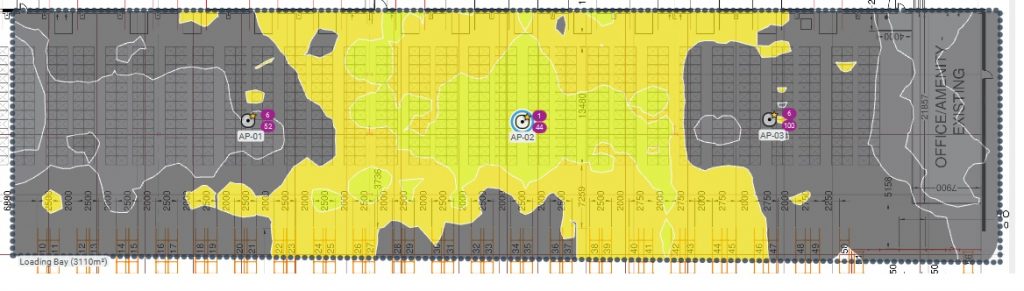

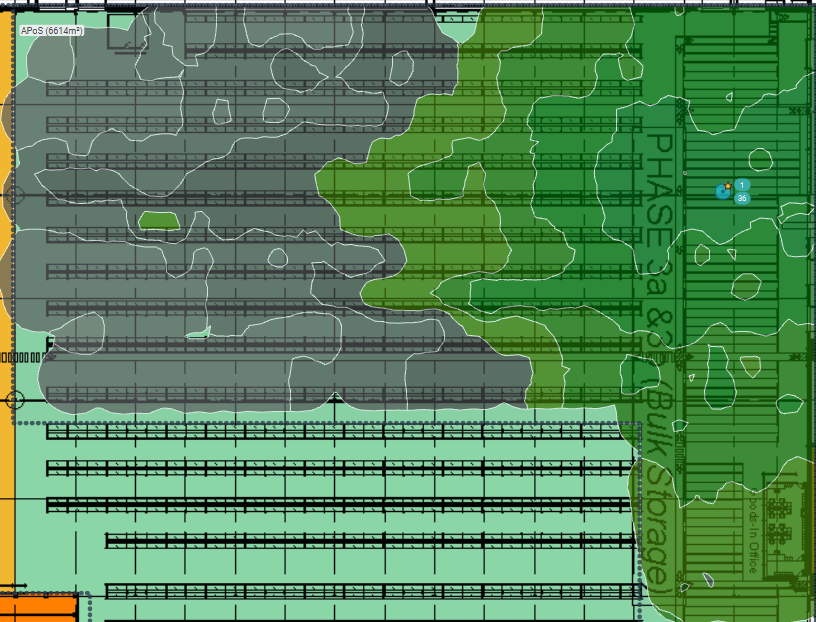

Acceltex – ATS-02695 – Picking/Depatch Areas and Loading Bays

For those who have worked in warehouse/distribution centres, there are often very large, open areas where pallets are broken down or re-wrapped on palletizers, it is also common to see products stored in these areas temporarily before being loaded onto transportation. This changes the requirements for RF coverage quite dynamically depending on the total number of movements ie: how busy the warehouse is at a particular time.

So often I have seen these areas serviced simply by installing omnidirectional APs on the perimeter of the building, generally around the loading bays, unfortunately, this approach typically results in a high percentage of RF bleed from the loading areas into the aisles, which can have an impact on mobility for clients moving between coverage areas and is also problematic during peak periods, where a lot of product is stored awaiting despatch and often stacked on top of each other, effectively creating an unforeseen attenuation area, causing further problems for operatives that need to scan pallets at ground level, when the line of sight to the AP is heavily impaired.

For this reason, I again prefer an overhead approach, as it offers a consistent line of sight between client devices and APs, minimises bleed into the aisles and avoids the problem with RF shadowing created when pallets are stacked on top of one another before depatch.

As a result, the characteristics I want to see from an antenna for this particular use case is a tighter, yet uniform coverage pattern, and one less pervasive when compared to an omnidirectional equivalent.

Previously I have used antennas supplied by the AP manufacturer for this purpose, but there are two Acceltex products that peaked my interest and ticked all of these boxes, the ATS-02695, of which i already had a sample and the ATS-01117, which has an even tighterHorizontal (65°) and Vertical Beamwidth (62°_ @ 5GHz with an increased gain of 7dBi vs the 4dBi of the ATS-02695.

An example of this can be seen in the following validation of an older installation using the Cisco 2566P4W, in similar circumstances, deployed to favour the wider beamwidth of 110° providing more elongated coverage of the loading bay area below, there is a tool for every job!

That being said, the opportunity presented itself on a separate occasion to do a quick APoS survey to validate what I hope could be achieved using a product which seemed to lend itself to this particular use case.

APoS Setup

Using the Vantagepoint mast once again, the ATS-02695 antenna was mated to a Cisco Catalyst 9120AXP AP at a height of 7m and configured with a TXPower of 14dBm.

NB: The racking area closest to where the AP was situated was empty at the time, which is reflected in the results, as the coverage is more pervasive than I would expect if the racks were more densely populated.

For the record, this wasn’t primarily the reason I was at this warehouse, as was putting another product through its paces, the Cisco Catalyst 9166D1, that will be for another post!

Survey Path

Once the AP was up and running, the following survey path was taken, these aisles are 100m long, which proved to be long enough to determine where the measured signal dropped below a pre-determined threshold of -65dBm.

APoS Results

Whilst this wasn’t an exhaustive test, it is clear from the initial results that we are far exceeding the intended coverage area, RF is bleeding a long way into the aisles, especially from the POV of the sidekick likely assisted by the reflective nature of the physical environment, when simulating a mobile device, this is more indicative of what I was hoping to see, and requires further testing to find a sweet spot for TXPower whilst maintaining a balance between AP/Client RSSI and SNR, still a promising step in the right direction.

The distance between the end of the racking at the perimeter wall isn’t particularly big, only 23m, which might not suit the beamwidth for this particular product, and the ATS-01117 could be considered instead, to pull the coverage area in tighter and further limit the bleed into the aisles.

Hypothetically, If I were to commit to designing a solution for this warehouse, the following coverage areas would be defined within the loading bay areas, and testing repeated, something I hope to complete in detail when time allows.

Ultimately I believe this is why it is crucial, especially in large, complex environments not to completely rely on the planning tools, bring this equipment to the field, run through the various iterations, and make better, more informed decisions, think of it as risk mitigation, but also a valuable learning experience.

Hopefully, this proves useful for anyone else working in these environments, any comments or feedback is welcome.