Introduction

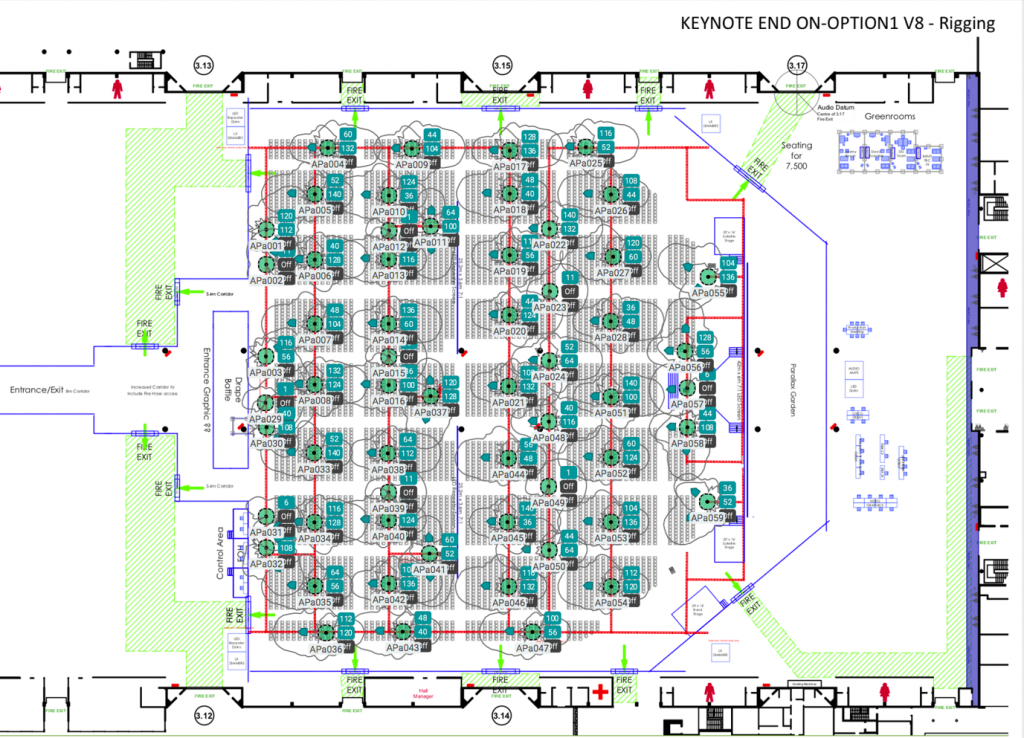

One of the considerations when deploying APs into any high-density environment, is, where do you put them? For this type of venue, uses cases are dissected across many common areas, for the purpose of this discussion however, we are focused on the main arena where live performances will take place, sometimes also referred to as the “Bowl”. A term often attributed to similar deployments in sports venues worldwide.

Whilst there are many examples of overhead installations for these types of deployments, Cisco Live being one great example using their AIR-ANT2513P4M-N dual band antennas. Figure 1.0

In an open arena like the venue that we are deploying into in Manchester, there is no option to mount overhead due to the need for there to be an unrestricted line of sight to the main stage, and that to achieve the necessary density, it would be physically impossible/improbable to install the number of antennas required to meet the density requirements.

Yes, there is a gantry, to which ME (Mechanical/Electrical) equipment and lighting will be attached, which will be discussed in another post, but this can only cover the standing area in the middle of the arena.

The seating tiers require an alternate approach, enter the pico cell design.

Figure 1.0 – Cisco Live Keynote – Barcelona 2020

Pico cell designs have become extremely popular for stadium deployments over the past decade, and refined to the point where capacities of over 70,000 occupants can be supported. And have proven very successful.

Wi-Fi Scores 100X Data Increase at the Super Bowl over 10 Years for 20X Less Money than 5G

Much of the research and fine tuning required to achieve these results are shared by members of the wireless community, especially from deployments within the US, if you have ever taken the time to watch or listen the material that Chuck Lukaszewski and his colleagues at Aruba have released based on their experiences deploying similar systems, you’ll appreciate the problem at hand. For that matter, i absolutely encourage you to seek out these presentations at events like WLPC and Tech Field Day, they are extremely insightful.

The basic premise of a pico cell wireless design, is that instead of providing coverage overhead, APs are installed under visitor seating. The key aspect of this approach is that human bodies themselves are used to attenuate RF signals and thus attempt to achieve a better channel re-use factor. Essentially, the more occupancy within the stadium, the higher the attenuation factor, thus a better performing wireless network due to lower co-channel contention. Airtime in these types of deployments is a valuable commodity!

To meet the requirements, APs need to be installed into NEMA (US) or IP Rated (International) enclosures. These enclosures must be securely affixed to the building superstructure, tamper proof, ascetically pleasing, easy to maintain and/or gain entry too to perform any required servicing or swap outs of active equipment.

Enclosures must also be robust enough to withstand common interactions with visitors to the stadium and provide sufficient protection from any manmade or environment hazards, whilst not inhibiting propagation of RF signal or by introducing any negative RF behaviours.

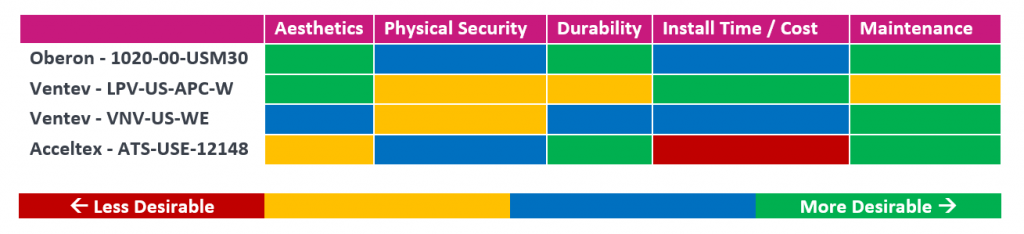

Whilst this is a niche corner of the wireless market, there are several vendors who cater for these specific requirements, but there are no detailed technical comparisons of different products.

Enclosures on Test

To ensure the necessary due diligence was carried out on behalf of our customer, 4 enclosures were selected that meet with the requirements of the specification and intended use cases. Each of these products are specifically designed to be installed into a large public venue (LPV) and placed in the main arena/bowl area, under stadium seating.

| Vendor | Description | Part Code | Datasheet |

| Oberon | NEMA-4 Plastic Wi-Fi Access Point Enclosure | 1020-00-USM30 | Datasheet |

| Ventev | Low Profile Under Seat Enclosure | LPV-US-APC-W | Datasheet |

| Ventev | NEMA 4X-rated UL50E Certified Wedge Enclosure | VNV-US-WE | Datasheet |

| Acceltex | ABS Under Seat Enclosure | ATS-USE-12148 | Datasheet |

An independent review of each enclosure has been carried out and a score determined based on the observations made during testing.

Each product is evaluated in each test category and a value assigned denoting whether the attributes observed were more, or less favourable for an LPV under seat deployment, based on the project specification.

A Cisco AP (C9130-AXI) has been used in all tests to evaluate ease of installation and help to identify any constraints found during the process. This is the flagship model in the Cisco Catalyst WiFi 6 product family and one of the largest indoor APs w/ integrated antennas, thus able to validate manufacturer claims for interoperability with each enclosure.

Physical alterations to each enclosure to facilitate Installation of structured cabling has not been attempted, but observations were made to try and identify best practise and/or recommended procedures required to maintain the IP/NEMA rating of each enclosure once installed.

Test Criteria

The following test criteria were defined to score each enclosure.

- Aesthetics – How well the product integrates with the look and feel of the stadium design, whilst maintaining required functionality.

- Physical Security – Level of protection from tampering, theft, and un-authorised attachment to CNS network.

- Durability – Robustness towards physical interactions with stadium visitors and maintenance personnel.

- Installation time and cost – Effort required to install enclosure and fit AP.

- Maintenance – Ease of which to gain access to the enclosure once installed to perform proactive or reactive maintenance activity whilst maintaining aesthetics.

RF Attenuation Measurements

A critical factor in the performance of each enclosure is to verify that each product on test has little or no impact to RF behaviour or signal attenuation. Given that each enclosure is specifically designed to house an AP, it is assumed that materials used in construction do not possess any metallic properties and allow both 2.4 and 5Ghz frequencies to pass un-impeded.

Whilst this test was not conducted under laboratory conditions, the tests should be able to determine if there were any significant variances between the cover/shield being removed from the enclosure vs when installed.

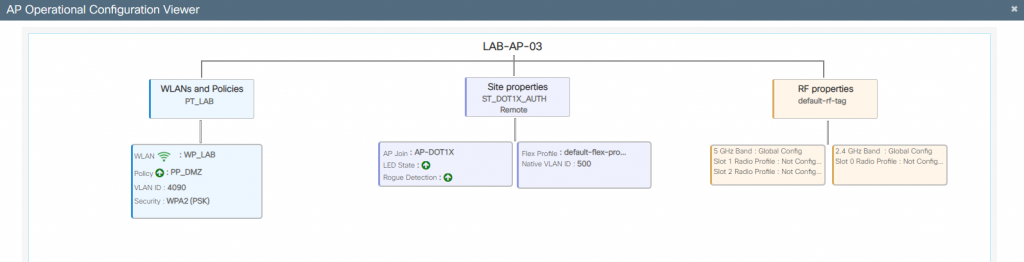

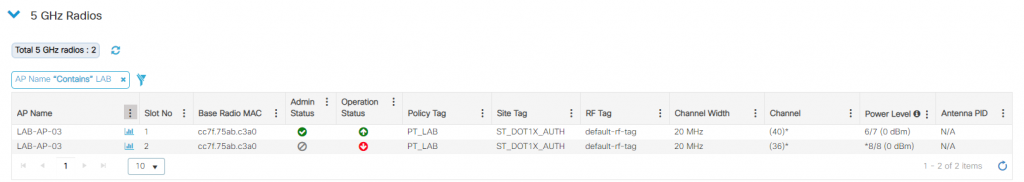

To verify this, the following LAB setup was used.

- Ekahau Sidekick v1 – Firmware v2.5.53

- Ekahau Analyser – App v2.0.2

- Apple iPad Pro – iOS v15.7

- Cisco 9800-CL Wireless Controller – IOS-XE v17.9.

- Cisco 9130-AXI Access Point – IOS-XE v17.9

Radio Configuration

- A single BSSID was configured on the LAB AP named “LAB”.

- Transmit power on both radios was hardcoded to the same power level (0 dBm – Power Level 6)

- The Ekahau Sidekick was placed in clear line of sight – 2m away to account for FSPL (Free space path loss) over the first meter.

- Sample measurements were observed within the Ekahau Analyser App with the enclosure cover removed and when installed.

- Test repeated 3 times with the enclosure cover removed and when installed, then a mean average recorded.

- Channels 1 (2.4Ghz) and 36 (5Ghz) were selected to allow for the least amount of signal attenuation ie: Lowest frequency within each respective band.

Cisco 9800 – Test Tags and Profiles

Radio Configuration (2.4Ghz)

Radio Configuration (5Ghz)

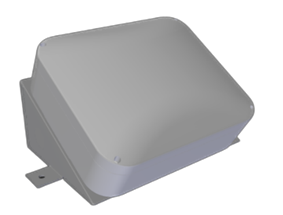

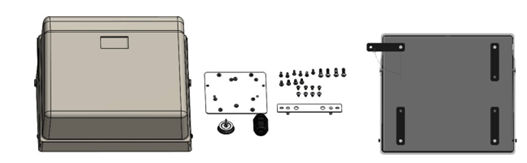

Oberon – 1020-00-USM30

The Oberon 1020-00-USM30 is part of the Skybar collection, specifically targeting outdoor and public venue access point enclosures.

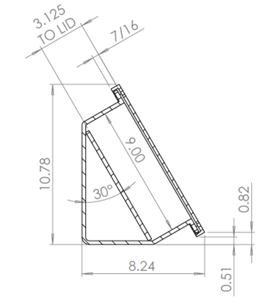

This model in in the 1020 range is comprised of three component parts, a Grey Textured UL94-V0 Polycarbonate Enclosure Base, a Grey Textured UL94-V0 Polycarbonate Enclosure Cover, mated with a Grey Powder Coated Aluminium 30° Angle Bracket. All of which can be painted or wrapped, should there be a requirement to conceal it further.

The enclosure and cover can be installed independent on the angle bracket but doing so provides an easy ingress point for structured cabling and attachment of a compression fitting to maintain a weatherised seal.

The enclosure base is attached to the angle bracket using 4 x 8 x 5/16 in. Phillips Truss Head Screws, affixed from within the enclosure and the enclosure cover is attached directly to the base using 4 x M4 x 20 mm Temper Resistant Torx Screws.

To ensure that NEMA 4 rating is maintained, Oberon give specific instructions to ensure that the enclosure cover is affixed to the base and screws tightened to 8 In-Lbs, as there is a gasket seal that runs around the inside edge of the base.

Several options exist to attach the angle bracket to the building superstructure, by way of 2 flanges that protrude from either side, logic would dictate that these fixings be a concrete anchor bolt or screw to maintain physical security and prevent accidently detachment.

3 options exist for ingress of structured cabling, plastic is easily drilled and machined for custom cable ingress and installation either via pre-formed cut-outs on the left- and right-hand side of the angled bracket, where a compression fitting can be directly attached, or for installations that allow for it, such as placing the enclosure directly over a network outlet, there is a large rear cut-out. A steel cover is provided should this not meet with the intended use case which can be fastened to the bracket using 4 x 8×5/16” screws provided.

Physically, the form factor is compact and aesthetically pleasing, allowing for easy access to the front of the enclosure without additional modifications. The design of the enclosure itself, allows for it to be fitted flush with the wall allowing for maximal room under the seat.

Access Point Compatibility (Listed)

- Aerohive – AP110/120

- Aruba – AP-135, AP-205, AP-215, AP-225, AP-303, AP-305, AP-315, AP-325, AP-505, AP-515

- Cisco – 1600i/1700i/2600i/2700i/3500i/3600i/3700i Series, 1830i/1850i Series, 2800i/3800i Series, 9120AXI, 9130AXI

- Extreme Networks – AP305C, AP410i, AP460i, AP505i / AP510i

- Mist – AP41

- Ruckus – R550, R650

- Ubiquiti – UniFi UAP-AC-HD

Physical Measurements

| Height | Width | Depth | Weight |

| 358mm | 185mm | 242mm | 1.4Kg |

Performance Rating

Designed to NEMA 1, 2, 4, 4X, 12, and13, and IEC529-IP66 specifications for indoor/ outdoor wet, dirty, or corrosive environments. NEMA PW ancillary rating for power washing environments. UV stabilized for exposure to direct sunlight.

The operating temperature of this enclosure is not stated, however the AP maximum operating temperature should be de-rated by 11° inside the enclosure, when solar loading is not present.

Physical Security

- Comes with standard and tamper resistant screws.

- Can be affixed to solid structure using ground anchors or bolts (10mm)

- Enclosure base and cover would like resist casual attempts to gain access to the interior.

RF Measurements

The Oberon documentation states that this enclosure is “Virtually transparent to wireless signals”

Testing seems to support this, with a very small variance detected over the course of each test (+/- 2dBm) and in many cases, installation of the cover had no immediate impact.

| 2.4Ghz | 5Ghz | |

| Cover Removed | -56 dBm | -58 dBm |

| Cover Installed | -57 dBm | -58 dBm |

Supplied With

- (1) T-Bar Bracket

- (4) M4 x 20 mm Captive Phillips Lid Screws

- (4) M4 x 20 mm Captive Torx Lid Screws

- (4) #6 x 5/16 in. Pan Head Thread-Forming Screws for Plastic

- (4) #6 x 5/16 in. Flat Head Thread-Forming Screws for Plastic

- (4) Cushioning Washers

- (1) 30° Angle Bracket

- (1) Metal Double Gang Outlet Box Flat Blank Cover

- (4) #8 x 5/16 in. Phillips Truss Head Screws

- (4) #10 x 1/2 in. Phillips Pan Head Screws

- (4) #10 EPDM Rubber Sealing Washers

- (4) #10 Stainless Steel Washers

- Installation Instructions

- AP mounting plate provided separately – Usually supplied with compatible AP

Installation Time

- 20 minutes

- Separate actions required to mount angled bracket to base, including drilling and installation of weatherised glands for cable ingress.

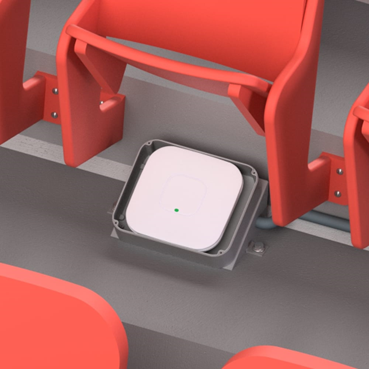

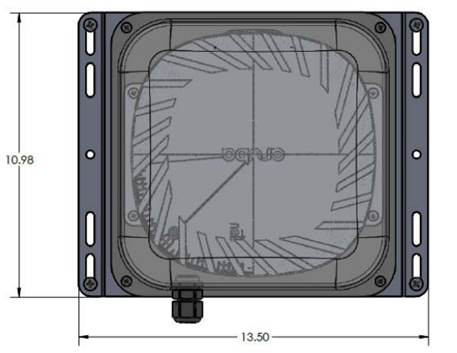

Acceltex – ATS-USE-12148

The AccelTex Solutions ABS under seat enclosure is the only enclosure available that is specifically designed for this type of LPV deployment.

It is NEMA 4x rated and formed as a single piece, manufactured from ABS plastic (Acrylonitrile Butadiene Styrene)

The acrylonitrile in ABS plastic provides chemical and thermal stability, while the butadiene adds toughness and strength. The styrene gives the finished polymer a nice, glossy finish.

As ABS has a low melting point, it enables its easy use in the injection moulding process and 3D printing. It also has high tensile strength and is very resistant to physical impacts and chemical corrosion. All of which are desirable properties for this particular use case.

The enclosure if formed of two parts, a moulded base and detachable cover, this is fixed to the base using 10-32 tampered resistant bolts, into jack nuts installed into each of the apertures.

The interior design of the enclosure is basic, with no ingress points for structured cabling or options to fix to a permanent structure, these must be created manually by the installer and all associated fixings provided separately.

There is a backplate onto which a vendor specific AP bracket can be attached, which places the AP on 30° angle.

Physically, due to simplicity in the design, the form factor is relatively compact and inconspicuous, and although not stated in the documentation, could theoretically be painted, or wrapped to obscure it further from view.

Access Point Compatibility (Listed)

- Adtran/Bluesocket 1920, 1930, 2020, 2030, 3040

- Cisco 1602i, 1832i, 1852i, 2602i, 2702i, 2802i, 3502i, 3602i, 3702i, 3802i, 4800, 9115i, 9117, 9120i

- Cisco Meraki MR18, MR20, MR32, MR42, MR52, MR53, MR70

- Extreme AP 3705, 3715i, 3801, 3805i, 3825i, 3912, 3935i, 3965i, Extreme

- WiNG AP 8432

- Mist AP33, AP43, AP45, AP45E

Physical Measurements

| Height | Width | Depth | Weight |

| 279mm | 368mm | 334mm | 1.1Kg |

Performance Rating

A weatherised seal is provided by way of a rubberised gasket that runs around the interior of the enclosure, once mated with the cover and screws tightened, combined with the one piece formed plastic exterior should be able to maintain the NEMA 4X / IP66 rating.

Caution must be given to physical installation of weatherised glands for cable ingress, as these must be created manually, as there are no cut-outs available.

The operating temperature of this enclosure is stated as being-20 to 240°F (-28 to 115°C)

Physical Security

- Comes with 10-32 tamper resistant bolts fixed into jack nuts.

- Can be affixed to solid structure using ground anchors or bolts, but modifications must be made by installer.

- Enclosure base and cover would like resist casual attempts to gain access to the interior.

RF Measurements

ABS plastic can attenuate RF (radio frequency) signals. The extent to which it does so will depend on the specific frequency of the signal and the thickness of the plastic. In general, ABS plastic is a poor conductor of RF signals and can be used to block or reduce the strength of such signals. However, it is not a perfect shield and may not be effective at blocking very high frequency signal such as WiFi.

Testing seems to support this, with a very small variance detected over the course of each test (+/- 1dBm) and in many cases, installation of the cover had no immediate impact.

| 2.4Ghz | 5Ghz | |

| Cover Removed | -56 dBm | -56 dBm |

| Cover Installed | -57 dBm | -57 dBm |

Supplied With

- (8) 10-32 Temper resistant torx bolts

- AP mounting plate provided separately – Usually supplied with compatible AP

Installation Time

- 30 minutes depending on installation preference for ground anchoring and structured cable ingress

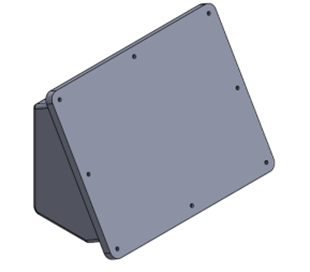

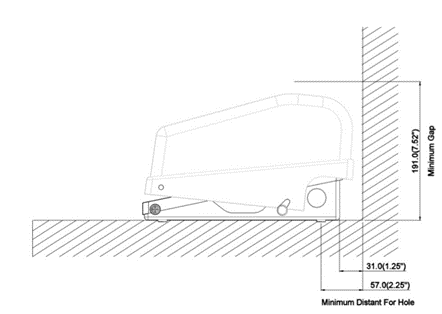

Ventev – VNV-US-WE

The heaviest unit on test, the Ventev VNV-US-WE wedge enclosure, is designed specifically for under the seat deployments in indoor or outdoor high-density environments, especially where both weatherised protection and deployment flexibility are mandated.

This model is NEMA 3 rated and meets requirements for the UL-50E, Standard for Enclosures for Electrical Equipment.

A protective Gore Vent is installed to prevent condensation and enclosure from overheating, whilst the physical design is intended to be inconspicuous, the polycarbonate material used is construction is RF transparent, UV-resistant, and paintable.

The VNV-US-WE model requires no additional assembly from the factory and comes with ingress routes for structured cabling pre-installed, along with the necessary fixtures and fittings to ensure the NEMA rating in maintained during installation.

The enclosure can be affixed to any flat, solid surface using 4 flanges extending out from the heavy gauge 5052 aluminium base, using appropriate concrete screws or anchor bolts.

Physically the form factor is very compact and aesthetically pleasing, although a more neutral colour would have been preferable for the polycarbonate cover, it can easily be painted.

Fixtures and fittings for AP installation are provided as part of the accessory kit shipped with the enclosure, which affix to an internal swivel mounted bracket, allowing for a range of tilt from 0° to 33° (Measured)

Once installed, the cover is secured using a pair tamper resistant bolts or screws are provided as part of the accessory kit shipped with the enclosure.

Due to the physical design of the enclosure, it cannot be installed flush to a wall, and a 32mm gap but be left so that the lid can be removed from routine maintenance.

Access Point Compatibility (Listed)

- Cisco: 1852i, 2800/3800i, 9115i, 9117i, 9120i, 9130i

- Aruba: 300 Series, 515, 535

Physical Measurements

| Height | Width | Depth | Weight |

| 165mm | 324mm | 284mm | 2.7Kg |

Performance Rating

The enclosure is UL 50E rated and constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and settling airborne dust, lint, fibers, and filings); and to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing).

No recommended operating temperature of this enclosure is stated within the documentation.

Physical Security

- Comes with tamper resistant screws for affixing cover to base once AP installed.

- Mounting Feet/Flanges fitted from factory to allow fixation to solid floor using appropriate bolts and/or anchors.

- Enclosure cover would like resist casual attempts to gain access to the interior, enclosure based would require a much more robust approach.

RF Measurements

The Ventev documentation states that this enclosure is “RF Transparent”

Testing seems to support this, with a very small variance detected over the course of each test (+/- 2dBm) and in many cases, installation of the cover had no immediate impact.

| 2.4Ghz | 5Ghz | |

| Cover Removed | -57 dBm | -55 dBm |

| Cover Installed | -57 dBm | -55 dBm |

Supplied With

- AP Adapter Plate and screws

- Aruba 5xx T-Bar Adapter Bracket

- Weatherised glad to protect cable entry point from water ingress

- AP mounting plate provided separately – Usually supplied with compatible AP

Installation Time

- 20 minutes.

- Interior wedge bracket does need to be removed to install AP adapter plate using 8mm socket wrench

- Protective covers for cable ingress points can be removed using 27mm socket wrench

Ventev – LPV-US-APC-W

The Ventev LPV-US-APC-W is a sturdy, lightweight, economical, and very low profile, under seat enclosure, designed specifically for LPV environments requiring protection of an AP or other wireless equipment from harsh weather, tampering and impact.

The compact cover and mount assembly is constructed with a white polypropylene cover, a powder-coated heavy gauge aluminium mount plate, gasket, cord grip, breather vent and hardware to mount to concrete. The mount plate itself is offset from ground level by 15mm to further reduce risk of water ingress and can be affixed to a concrete superstructure using screws supplied with the enclosure.

The design is simplistic and aesthetically pleasing, allowing for installation under seating in spaces below 125mm.

The enclosure cover is secured to the base using tamper resistant screws and internally a universal mounting plate is presented on which a manufacturer supplied bracket can be attached to place an AP on a horizontal axis. Some APs, such of Cisco Catalyst models will attach to this bracket natively.

There are no pre-defined ingress points for structure cabling into the enclosure, but two weatherised glands are provided, which requires manual intervention to drill a 20mm pilot hole for installation of the gland at a location determined by the installer.

Access Point Compatibility (Listed)

- No specific vendors or model listed but noted that it should support the majority of APs in the market, the installation plate inside the enclosure does seem flexible enough to allow for a number of different options.

Physical Measurements

| Height | Width | Depth | Weight |

| 102mm | 342mm | 279mm | Not Stated (1kg est) |

Performance Rating

Whilst there is no specific NEMA or IP rating noted on the documentation, it does state that it is watertight and capable of withstand high pressure washing.

No recommended operating temperature of this enclosure is stated on the Ventev website.

Physical Security

- Comes with tamper resistant screws for affixing cover to base once AP installed.

- Can be affixed to solid structure at 4 points, using ground anchors, bolts, or concrete screws (Supplied)

- Enclosure cover would like resist casual attempts to gain access to the interior, but the exterior cover does not seem to be highly resistant to damage and can be compressed under load.

RF Measurements

The Ventev documentation does not make any statements regarding RF transparency of this enclosure.

Testing seems to support this, however signal strength seemed to improve and 5Ghz and deteriorate more than expected on 2.4Ghz when the cover was installed.

| 2.4Ghz | 5Ghz | |

| Cover Removed | -55 dBm | -56 dBm |

| Cover Installed | -59 dBm | -55 dBm |

Supplied With

- (1) T-Bar Bracket

- (8) 6 x 30mm Masonry/Concrete screws

- (8) 6 x 20mm Tamper resistant torx screws

- (4) 6 x 25mm White Phillips Truss Head Screws and wall plugs

- (4) 4 x 7mm Phillips Truss Head Screws

- (4) 3 x 7mm. Pan Head Thread-Forming Screws for Plastic

- AP mounting plate provided separately – But supplied with compatible AP

Installation Time

- 15 minutes or less depending on use case and AP interoperability with installer plate

Test Summary

Following a technical review of each of the enclosures on test, results have been summarised the findings in the following table.

It should be noted that this is a purely subjective opinion, driven heavily by the particular end user and installation requirements.

Oberon (1020-00-USM30)

The Oberon 1020-00-USM30, when paired with angled bracket provides a compact, robust, and easy to install enclosure, which combined with its NEMA 4 and IP66 rating ensures long term investment protection and deployment flexibility.

Maintenance or requirements to perform reactive troubleshooting tasks of active equipment within the enclosure is simplified, with un-restricted access to the enclosure cover once installed, tests shown that it also has little or no impact on RF attenuation.

Pros

- Aesthetically pleasing and can be concealed further if necessary.

- Compact.

- Rugged.

- Easy to maintain.

Cons

- No locking mechanism. Relies on tamper resistant screws.

- AP can only be mounted at 30° angle in this configuration.

Acceltex (ATS-USE-12148)

The Acceltex ATS-USE-12148 enclosure provides a simple, robust, environmental resistant enclosure with flexible installation options, some installers may be discouraged by the amount of additional manual effort required to affix to a permanent structure, install the AP bracket and manually create a weatherproof ingress route for structured cabling, but the material can be drilled easily without comprising structural integrity, although It is unclear from the documentation what would be required in order to preserve the NEMA 4X/IP66 rating.

Due to the height once installed, it may present some installation challenges for certain seating configurations but should generally accommodate a wide number of use cases.

Maintenance of the enclosure is simplified, with un-restricted access to the front of the enclosure once installed and tests shown that it has little or no impact on RF attenuation.

Pros

- Simple design.

- Rugged.

- Easy to maintain.

Cons

- No locking mechanism. Relies on tamper resistant screws.

- No fixtures installed to allow easy fixation to solid surface, must be installed manually.

- No cut-outs or ingress points for structured cabling, must be installed manually.

- May not fit under some seating installations due to height.

- AP can only be mounted at 30° angle in this configuration.

Ventev (LPV-US-APC-W)

The Ventev LPV-US-APC-W is an excellent example of a simple, compact, and easy to install enclosure that would be well suited for LPV environments where space is constraint.

Attachment of APs or other wireless equipment is extremely quick and efficient, which should limit the overall time which to install this enclosure in large quantities, but some manual intervention is required to ensure that the cable ingress points remain weatherwise.

Consideration should also be given to installation and any ongoing maintenance, as it may prove challenging, if installed into a seating arrangement that limits the available space in which to gain access to the fixings used to attach the cover to the base.

Dependent on the intended use case and other external environmental factors, some installers may also be concerned that the enclosure does not have a NEMA/IP rating assigned.

Pros

- Simple design

- Aesthetically pleasing and can be concealed further if necessary

- Low profile to accommodate wide range of under seat installation

- Easy to install

- Very broad range of AP interoperability

- Supports mixed use cases

Cons

- No locking mechanism. Relies on tamper resistant screws, but lock could be retrofitted.

- Maintenance may prove difficult if installed under seat and space constraint.

- External cover not as durable as others on test.

- No NEMA or IP Rating

- AP can only be mounted at 0° angle in this configuration.

- Gasket within the enclosure is loose and caution must be given during installation to ensure that the enclosure is watertight.

Ventev (VNV-US-WE )

The Ventev VNV-US-WE enclosure is compact, low profile and well considered from a design perspective, making it very well suited for the intended use case. Flexibility to position an AP within the enclosure at angles between 0° and 33° (Measured) is a highly desirable feature, not seen in competitor products and allows for a greater degree of optimisation of the physical RF design, especially in LPV or very high-density environments.

Whilst the base is heavily resistant to accidently or intentional damage, the polycarbonate cover is not as robust as other enclosures and might be more prone to accidental damage over the life of the installation.

There are also some limitations to how the enclosure can be installed to allow for access to the interior once affixed to a solid surface, which may add unnecessary constraints to where the enclosure can be installed whilst remaining un-obtrusive to stadium visitors.

Pros

- Flexible AP and cabling installation options.

- Aesthetically pleasing and can be concealed further if necessary.

- Compact design.

- Easy to maintain.

- Could be retrofitted to further improve physical security but may void NEMA rating.

Cons

- No locking mechanism.

- External cover not as durable as others on test.

- Cannot be installed flush to vertical surface.

- Installation of AP adapter plate requires removal of AP bracket.

Conclusion

All the enclosures on test met with the minimum attributes that would be expected from an enclosure designed for this particular use case, the overall design of each sample is well considered, and all demonstrated positive qualities that would benefit a wide range of LPV deployments.

Whilst the criteria used to determine which model was more or less favourable were closely aligned with one another, the Oberon 1020-00-USM30 model is the best suited for this particular environment, and also favoured by the customer.

Whilst not alone within the 1020 product family, this configuration scored particularly well in all areas and provides a great amount of flexibility for both installation, concealment, and long-term maintenance, whilst being able to support all 6th Generation WiFi APs and accommodate future standards without additional modification or replacement of the physical enclosure.